Copper cable recycling

Shredding and dry separation from the insulating part ensure that the raw material re-enters the market. Processing is carried out by means of processes that are typically mechanical and air-driven. The copper is fed for processing into the plant, which consists of extremely sturdy shredders that can operate on a large amount of electrical cables. The copper then undergoes volumetric reduction, shredding and subsequent sorting.

The same plant can also work on large-diameter ironclad cables.

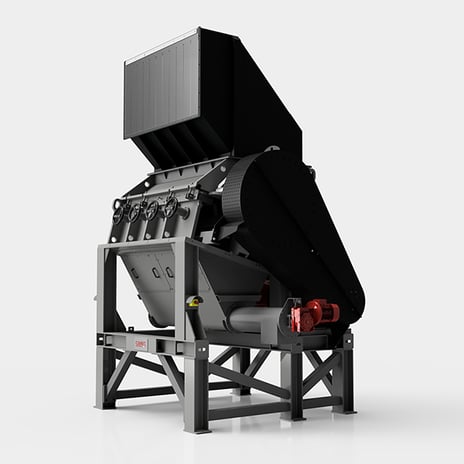

Single-shaft shredder GRR280

The shredders in the GRR line are suitable for various materials in applications calling for lower throughputs. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- Compact dimensions

- The bearings are amply separated from the shredding zone

- Parallel shaft gear reducer

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.

Granulators - MG400

MG400 is a line of medium power granulators.

Electric motor drive and grid with reduced size holes to obtain very fine piece size.

Granulators - MG800

MG800 is a top-of-the-range granulator suitable for heavy-duty work cycles.

The generously sized frame is designed to withstand bending and twisting moments, also when working with very tough materials.

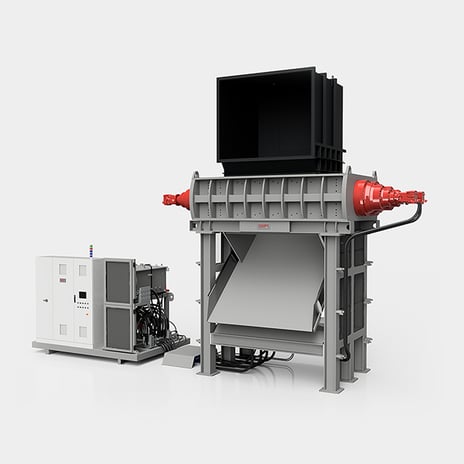

Rotary Shears - CR2A645

Model CR2A645 is specifically designed for heavy duty work on high wear materials. Ideal for volumetric reduction and coarse shredding of steel waste, ferrous scrap, or material in high-density bales.

- Shredder with two independent working shafts to reduce the rpm

- Easy maintenance cutting chamber with various blade configurations

- Wear-resistant cutting tools

- Customizable base and hopper for material loading and discharge

- Control panel with PLC to manage the machine, integration with other machines, the emergency circuit and safety of the mechanical parts