Oil filter recycling

The recycling process is determined primarily by the materials that make up the filters and the presence of lubricating oils. Oil is removed from the used filter by draining. The oil is stored together with the lubricating oils, while the filter volume is reduced by shredding. The treatment is completed when the plate is separated from the filter paper.

Single-shaft shredder GL650

GL650 with 650 mm rotor is a single-shaft shredder with radial pusher and hydraulic motor drive able to guarantee very high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Planetary gear reducers

Find out more

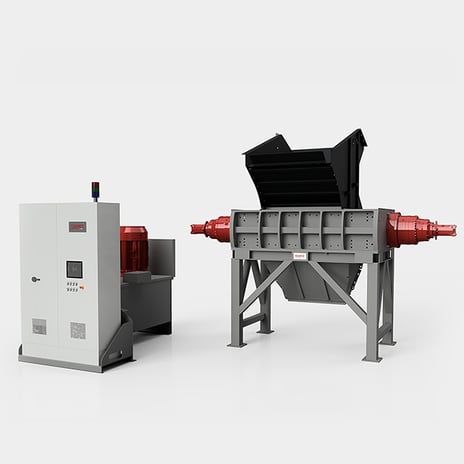

Two-shaft shredder TR2A450

TR2A450 is a shredder suitable for heavy duty work cycles.

The generously sized frame is designed to withstand bending-twisting moments, also when shredding extremely tough materials.

- Fabricated arc welded steel shredding section (30 mm gauge plate)

- Bearings amply separated from the shredding zone

- 2 hexagonal section 200 mm shafts

- Independently driven rotors

Find out more