Tank and bumper recycling

Motor vehicles contain a large number of homogenous plastic parts, which pose no particular problems during recycling: the bumper is made of polypropylene; seat padding is made of polyurethane; tanks are made of high-density polyethylene; wheel covers are made of polyamide; and dashboards and some headlights are also plastic items.

The car bumper and tank treatment plant is specifically designed by Camec for the transformation of rigid plastics into granules to be used as SRM (secondary raw material).

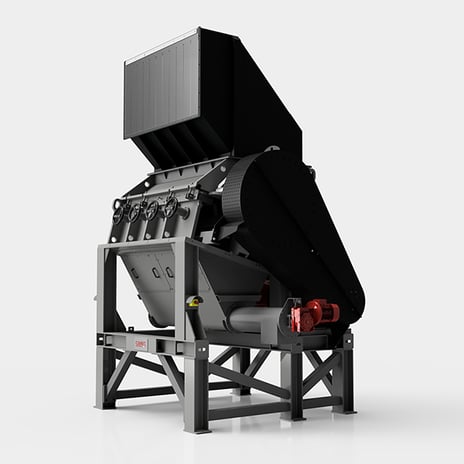

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.