PVC profile recycling

PVC is inherently a “low-carbon” plastic, is extremely durable and has an excellent cost/benefit ratio. PVC helps conserve resources and energy and, at the end of its life, can be recycled without losing its key properties.

PVC waste is finely shredded so that it can be processed into new PVC compounds ready to be melted and formed into new products.

Single-shaft shredder GRR280

The shredders in the GRR line are suitable for various materials in applications calling for lower throughputs. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- Compact dimensions

- The bearings are amply separated from the shredding zone

- Parallel shaft gear reducer

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

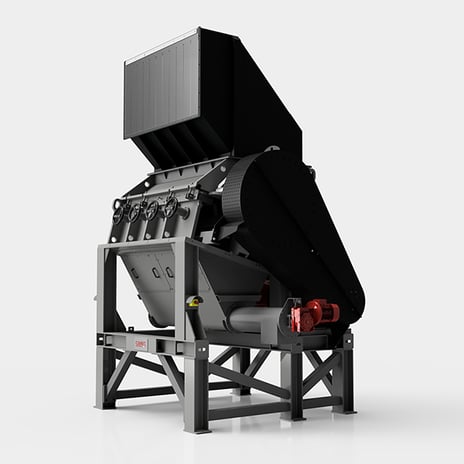

Double rotor shredder DR450

The DR line double rotor shredder is a versatile and efficient machine, designed for special processing of the material.

Control of the outfeed piece size typical of a single-shaft machine is combined with high throughput thanks to the presence of two independent rotors and two screens.

- Arc welded monobloc structure incorporating a cutting chamber and a motors compartment

- Bearings located well clear of the shredding zone

- Cylindrical rollers fixed with bolt-on cutter supports

- Fixed blades made from special hardened steel

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.

Granulators - MG400

MG400 is a line of medium power granulators.

Electric motor drive and grid with reduced size holes to obtain very fine piece size.

Granulators - MG800

MG800 is a top-of-the-range granulator suitable for heavy-duty work cycles.

The generously sized frame is designed to withstand bending and twisting moments, also when working with very tough materials.

Mobile Shredder DRM650

The DRM650 self-propelled shredder features a slow rotation double shaft and is crawler mounted, with hydraulic transmission.

- Arc welded monobloc structure composed of a cutting chamber

- Low speed rotation with high torque to the rotors

- Bearings amply separated from the shredding zone

- Cylindrical rollers with bolt-on cutter supports

- Cutting diameter of the cutters Ø650 mm

- Fixed blades in special hardened steel.

- Diesel engine and hydraulic transmission coupled directly to the engine

- Radio remote control for complete control of the machine