Rubber recycling

Rubber recycling refers to the recycling of a type of product that originates from a virgin material in the form of a granulate or powder and returns to that form when it is recycled.

The shredding process allows the rubber to become part of the compounds used by industry in numerous applications.

Rubber remains a highly recyclable material. The purpose-built Camec plant shreds and volumetrically reduces the rubber into granules, and then separates the plastic component from the other materials, such as metals and textile residues. The rubber is separated from the other materials and reduced to increasingly smaller particles.

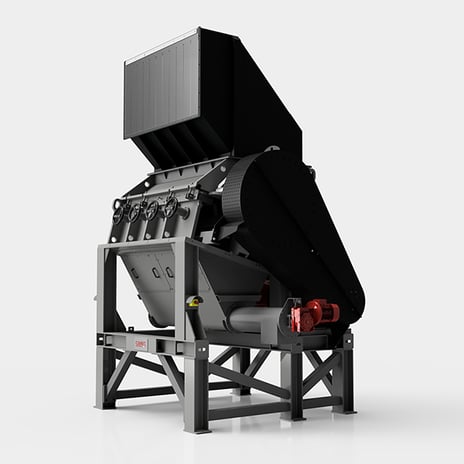

Single-shaft shredder GRR280

The shredders in the GRR line are suitable for various materials in applications calling for lower throughputs. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- Compact dimensions

- The bearings are amply separated from the shredding zone

- Parallel shaft gear reducer

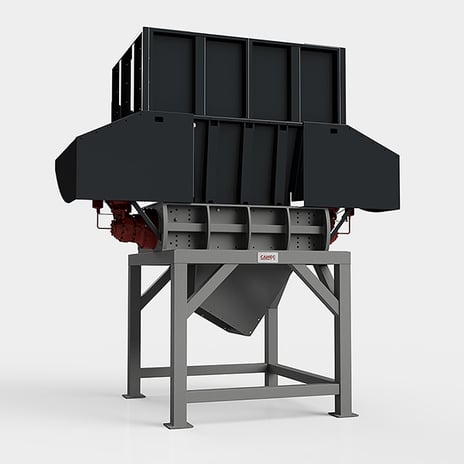

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Two-shaft shredder TR2A200

TR2A200 is the most compact shredder in the TR2A series.

Two-shaft shredders are designed for volumetric reduction and coarse shredding of the material.

The machine has electric motor drive with planetary gear reducers and can be equipped with an inverter on request.

- Shredding section in arc welded fabricated steel (15 mm gauge plates)

- Bearings amply separated from the shredding zone

- 2 hexagonal section 80 mm shafts

- Independently driven rotors

- Shafts C/C distance of 200 mm

Two-shaft shredder TR2A300

TR2A300 is a medium-small shredder.

Electric motor drive, with planetary gear reducers and an inverter on request.

- Shredding section in arc welded fabricated steel

- Bearings amply separated from the shredding zone

- 2 hexagonal section 130 mm shafts

- Independently driven rotors

- Remote connection for assistance

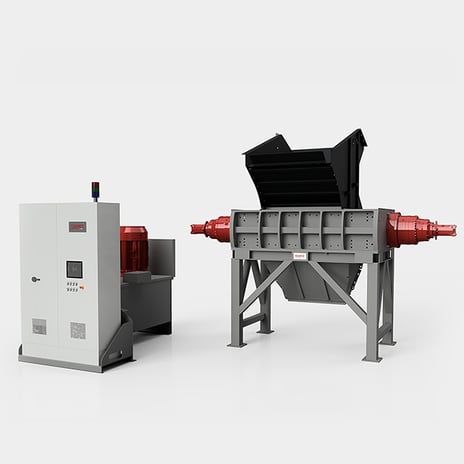

Two-shaft shredder TR2A400

TR2A400 is a shredder that can be supplied in an electric or hydraulic version.

The very low consumption of this machine saves energy, while the special steel blades allow very long life cycles.

- Fabricated arc welded steel shredding section (30 mm gauge plates)

- Bearings amply separated from the shredding zone

- Independently driven rotors

- 2 hexagonal section 210 mm shafts

- Independently driven rotors

- Remote connection for assistance

Two-shaft shredder TR2A450

TR2A450 is a shredder suitable for heavy duty work cycles.

The generously sized frame is designed to withstand bending-twisting moments, also when shredding extremely tough materials.

- Fabricated arc welded steel shredding section (30 mm gauge plate)

- Bearings amply separated from the shredding zone

- 2 hexagonal section 200 mm shafts

- Independently driven rotors

Two-shaft shredder TR2A520

TR2A520 is a top-of-the-range shredder suitable for heavy duty work cycles.

The generously sized frame is designed to withstand bending-twisting moments, also when shredding extremely tough materials, guaranteeing high performance levels.

- Bearings amply separated from the shredding zone

- 2 hexagonal section 240 mm shafts

- Independently driven rotors

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.