Textile waste recycling

Textile waste is often not recycled, when it could actually be recovered for various uses. Some examples of textile materials (derived from natural or synthetic fibres) that have reached the end of their life cycle are: carpet and rugs, combing, spinning, weaving, finishing and packaging waste. But also offcuts, headers, threads, shavings, clippings, all often classified as by-products.

Once in the plant, textile waste undergoes volumetric reduction treatment and subsequent shredding necessary to transform it into a material that can be recycled and reused.

Single-shaft shredder GRR280

The shredders in the GRR line are suitable for various materials in applications calling for lower throughputs. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- Compact dimensions

- The bearings are amply separated from the shredding zone

- Parallel shaft gear reducer

Single-shaft shredder GSR480

GSR480 with 480 mm rotor is a single-shaft shredder with radial pusher and electric motor drive. These shredders are equipped with a grid to allow uniform piece size at outfeed.

- High shredding surface area

- Compact dimensions

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the compartment

- Screen maintenance

Single-shaft shredder GS650

GS650 with 650 mm rotor is a single-shaft shredder with radial pusher and electric motor drive able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area and the maximum reliability

- Bearings separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

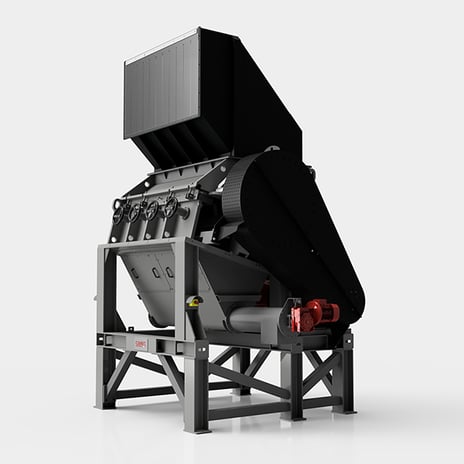

Single-shaft shredder GS900

The high-powered GS900 shredder is a top-of-the range single-shaft machine with radial pusher, equipped with electric motor drive and able to guarantee high hourly throughput.

- Arc welded monobloc structure for elevated robustness

- Large shredding surface area

- Bearings amply separated from the shredding zone

- Parallel shaft gear reducer

- Easy maintenance thanks to fully automatic opening of the service compartment and the screen

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.