One of the buttonholes of CAMEC offer is the revamping service for those recycling machines and plants that have exceeded ten years of life and therefore have mechanical components and technological solutions that are about to become obsolete.

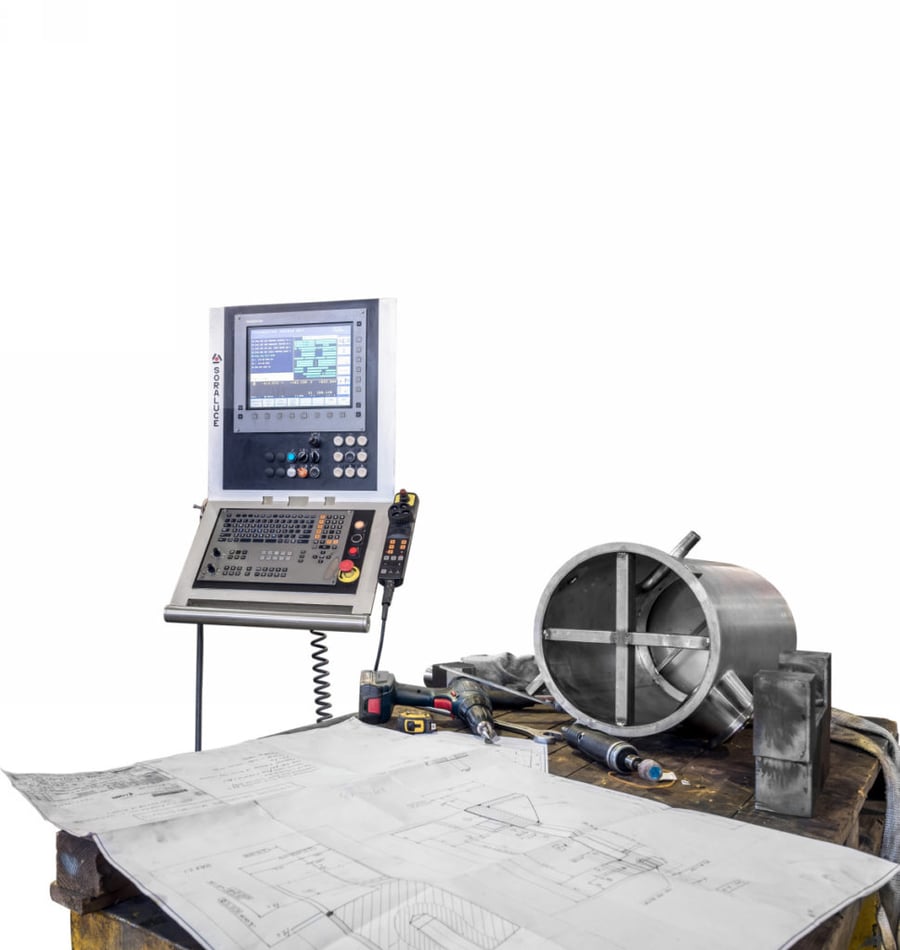

Revamping is a modernization process that makes it possible to make an outdated machine efficient, replacing some of its mechanical and plant parts, without however interfering with its overall structure. An intervention of this type makes it possible to significantly increase the efficiency of the system, extending its production life and postponing the need to replace it with a new machine.

It is important to remember that the revamping does not coincide with the normal maintenance of the system: the technicians who carry out ordinary and extraordinary maintenance, in fact, normally check the correct functioning of the system and replace any parts of the machine (such as the blades of a shredder) that have worn out over the time, while revamping is a real “restructuring” of the machine as a whole, aimed at improving its functionality by applying – where possible – more advanced technologies to improve productivity, efficiency and automation safety. Just as it happens when renovating a house, during a revamping intervention we do not limit ourselves to replacing certain worn parts with identical new ones, but radically rethink the way in which the machine operates, verifying the possibility of applying solutions more advanced technologies that will make the machine as a whole more effective and safer.

Revamping a recycling plant is therefore an extremely convenient choice that allows you to:

- Make the plant more efficient, improving its productivity

- Save money by making the machine more efficient with a lower cost and postponing the need to completely replace the automation

- Make the system less energivore (therefore less expensive and less polluting)

- Make the system safer for all the personnel who must work on it

- Prevent the occurrence of breakages, malfunctions and other problems that could lead to the blocking of the system and force it to be replaced.

To be sure that the revamping intervention is completed in the most effective, rapid and satisfactory way possible, it is essential to rely on the expertise of a partner who has in-depth knowledge of the machinery to revamp, its life cycle and its problems, and that at the same time is an expert in the sector, and therefore is able to propose the most advanced technical and technological solutions to improve the performance of the plant itself.

CAMEC, with its more than twenty years of experience in the production and installation of recycling machines, is able to study together with its customers the most suitable revamping intervention for their needs; CAMEC technicians, working in synergy with the client company, analyze the performance of the plant, check the conditions of all its components and suggest which interventions can solve the critical issues and improve the productivity and quality of the work carried out by the plant.

To find out more about CAMEC industrial recycling plants, download our catalogue now and contact us: we will be happy to answer your questions and offer you the solution most in compliance with your company needs!