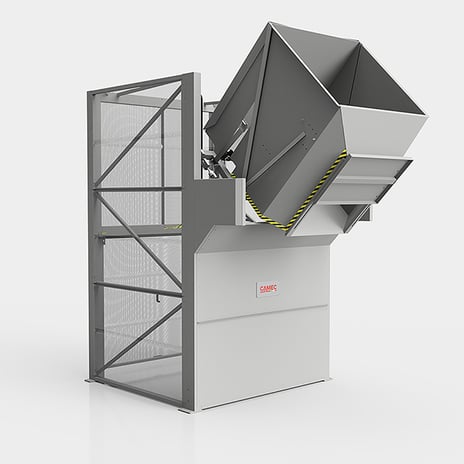

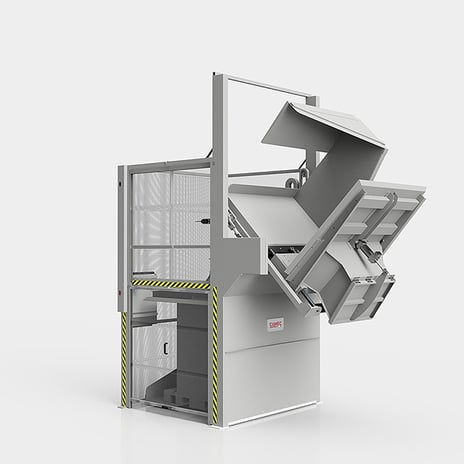

Tippers with Dosing Systems

These tippers are equipped with dosing systems for better distribution of the discharge of material, which is essential to optimise the efficiency of downstream processes, while ensuring greater precision and reliability in the handling of materials.

Guillotine Cover

Adjustable sheet metal panel, which, positioned on top of the trolley, allows adjustment of the material discharge opening.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.

Gravity Cover

The cover is partly fixed and partly hinged, while the movable part of the cover is free to open according to the length of the chains.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.

Cover with Pneumatic Actuator

A cover that is partly fixed and partly hinged, with the movable part of the cover controlled by a pneumatic-hydraulic actuator, which can retain the weight of the material during tipping until the actuator opening command.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.

Cover with Motorised Hopper

High-performance dosing cover with a PLC-controlled pneumatic actuator

with a spout and support surface on the octabin to allow the return of partially spilled preforms into the octabin itself.

- Electric-pneumatic operation.

- Chain lifting transmission.

- Bin locking grippers.

- Bin locking bar.

- Pneumatic valve for bin locking.

- Door retainer timed micron.

- Pneumatic-electric safety valve.

- Air connection: 90° connection for Rilsan hose diam. 8.