Recycling Division

Design and construction of machines for shredding industrial and municipal waste.

Single-shaft shredders

The single-shaft shredders of the GRR, GSR and GS line offer high quality standards and performance levels in the treatment of a wide range of material types. The presence of a grid allows uniform piece size at outfeed, preparing the material for downline processing stages.

Two-shaft Shredders

The two-shaft shredders in the TR2A line are designed to obtain volumetric reduction and coarse shredding of the infeed material and they can process any type of solid waste with high levels of performance and reliability. The material is shredded by two independently driven hexagonal section shafts.

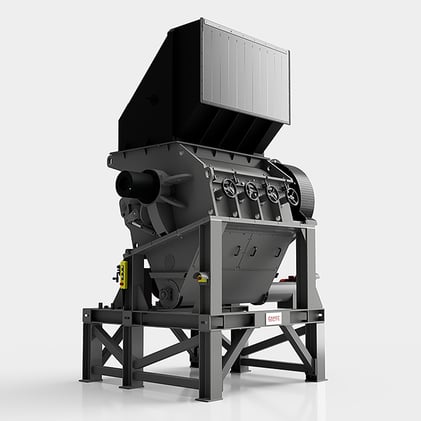

Quad-Shaft Shredders

The quad-shaft shredders in the TR4A line are flexible and efficient machines, designed for special processing of the feedstock. The presence of 4 independently driven hexagonal section shafts, combined with sizing grids makes it possible to obtain constant and controlled piece sizes of the material at outfeed.

Double rotor shredder

The double rotor shredder of the DR line is a flexible and efficient machine designed for special processing of the material, allowing uses in heavy duty applications and obtaining constant and controlled piece size.

Granulators

The granulators in the MG line are designed to shred and reduce mixed plastic material scrap.

Rotary Shears

The rotary shears of the CR2A line are specifically designed for the ferrous metals line, especially in severe conditions and with heavy duty work cycles.

Mills and Bag Openers

The mills and bag openers of the AS and LC line are expressly designed to open the material without reducing its volume, thanks to the use of special blades. These machines are used in facilities with a high material flow rates such as landfills and collection centres.

Mobile Shredders

The mobile shredders in the DRM and LCM line are the synthesis of CAMEC's experience in the construction of recycling machines. The company focuses its attention on two lines: DRM and LCM. The essential difference lies in the type of cutting chamber and in the choice between the crawler or hooklift version, as also in the type of drive system.

Hammer Mills

All structural parts of machine MV 2000 are made of heavy gauge arc-welded steel, forming a compact and robust unit.

Turbine

The horizontal turbine produced by Camec is designed to optimize the granulation process for both metallic and non-metallic materials.

Vega

The single-shaft bale openers of the VR line offer high quality standards and performance levels, especially in processing paper and cardboard in bales or as loose material.

Compactors and Balers

The compactors and balers in the P and SB line are machines designed to compact and reduce the volume of cans, containers, paper, cardboard, plastic and metal drums etc. by means of the pressure exerted on the waste materials by the pressing plate. The pressure is adjustable.

Transport Systems

Camec offers customers a comprehensive service for handling all types of treated materials. The transport systems of the TS line are available in different lengths and widths for loading and discharge of materials.