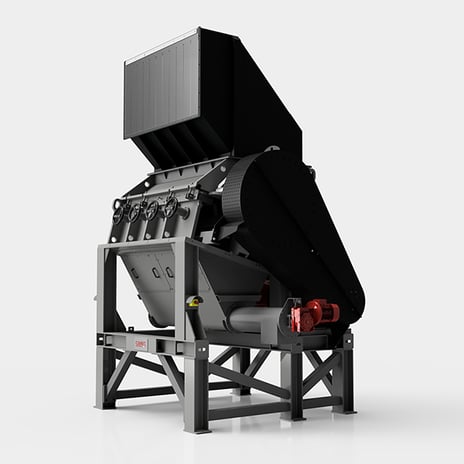

Granulators

The granulators in the MG line are designed for shredding and reduction of mixed plastic scrap produced in the injection moulding, extrusion, blow moulding and thermoforming sector or for granulation of rubber.

The special rotor configuration and the cutting angle used between blade and fixed blade retainer ensure energy saving and a significant reduction in dust formation during the granulation process. The robust structure with bearings amply separated from the cutting chamber makes it possible

to granulate the material with water spray jets inside the granulation chamber. This feature makes the machine extremely versatile and allows it to be used also to granulate materials with a low temperature melting point.

Granulators - MG300

MG300 is a line of versatile and compact granulators.

Electric moor drive and grid with reduced size holes to obtain very fine piece size.