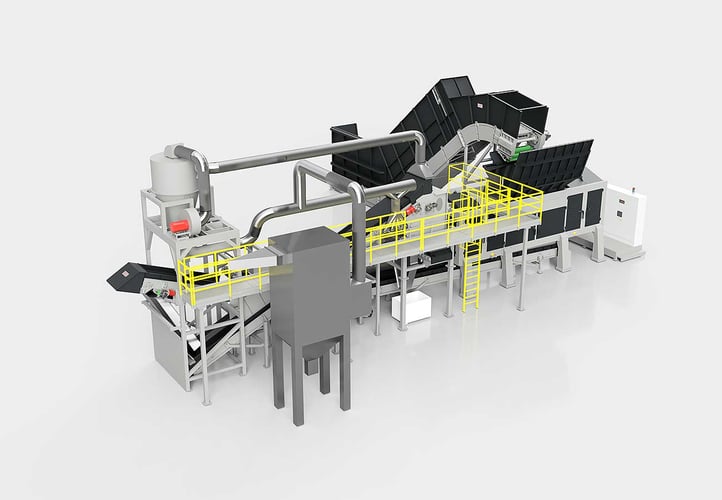

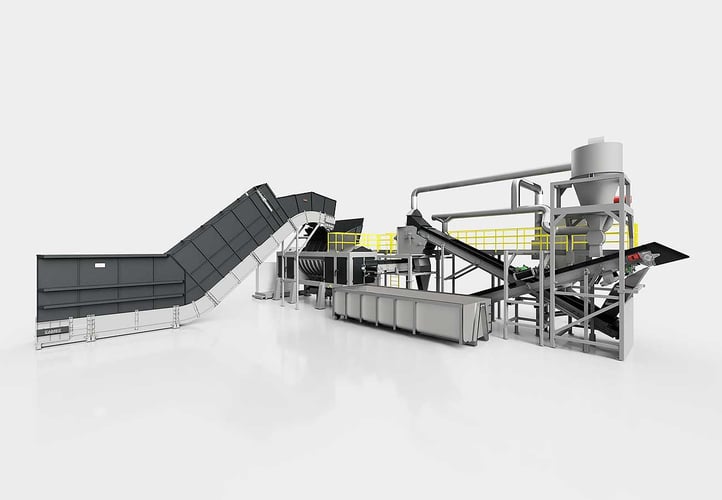

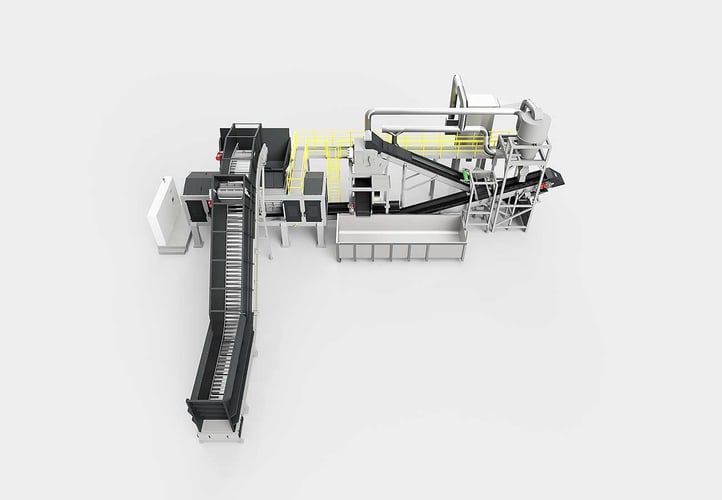

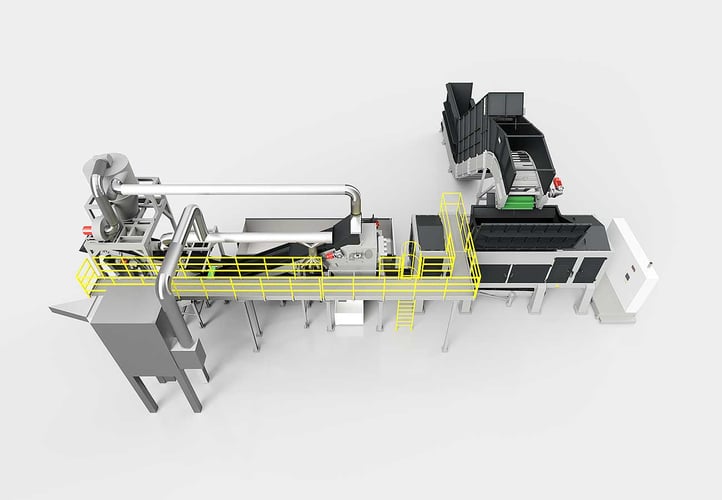

Pulper Waste and Rope Plant

The Camec pulper waste and rope treatment plant includes our patented solution that solves the needs of paper mills through a series of specific steps that separate the ferrous and non-ferrous fraction.

Description

For all entities specialising in paper recycling, CAMEC offers a plant specifically dedicated to the treatment of pulper waste, designed to separate its ferrous fraction from its non-ferrous fraction.

Thanks to this solution, which involves the use of our patented separation technology, the fractions obtained can be valorised to such an extent that the investment for the plant can be recovered in an extremely short time.

The material is shredded by means of a single-shaft shredder from the GS Camec line, equipped with a radial hydraulic pusher that compresses the waste inside the special cutting chamber.

By means of the rotor – fitted with special cutters – and a calibration grid, the waste is thus reduced to a controlled piece size for subsequent separation of the ferrous fraction from the other materials, mainly plastic.