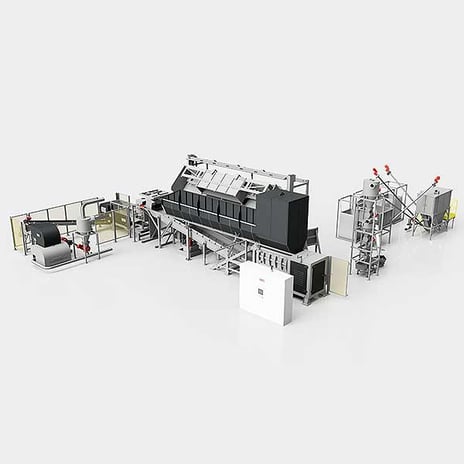

Plants

Camec’s complete plants for solid waste treatment and transformation are functional technological solutions, custom built to meet the needs of each client and to recover secondary raw materials of high purity and high quality.

Paper and Cardboard Plant

Camec plants dedicated to paper and cardboard are specifically designed to handle a highly abrasive material that requires the use of very powerful machines and wear-resistant tools.

Copper Cable Plant

Camec designs and manufactures turnkey plants fully customised to customer requirements for shredding electrical cables and the subsequent separation of the various materials.

RDF-SSF plant

The Camec RDF/SSF plant is designed to process industrial, domestic and commercial waste in order to obtain alternative fuels: RDF (refuse-derived fuel) and SSF (secondary solid fuel).

Sensitive Documents Plant

Camec produces purpose-built plants to meet very specific requests for the destruction of confidential documents by public or private bodies, organisations or administrations.

Scrap Iron Plant

Rotary shears and hammer granulators are the top of the Camec range for processing scrap metal.

Bulky Waste Plant

The bulky waste treatment plants designed and manufactured by Camec can shred and separate ferrous and non-ferrous metals, plastics, wood, paper and cardboard, or other materials according to customer requirements.

Wood Plant

Camec plants can shred any type of wood such as industrial waste, branches, logs, sawmill waste and wooden bulky waste.

By recycling wood, new materials can be obtained that are used for industrial purposes as well as the production of renewable energy.

Rigid Plastics Plant

The rigid plastics treatment plant is specifically designed by Camec for the transformation of hollow-body rigid plastics into granules to be used as SRM (secondary raw material).

Tyre Plant

The Camec plant for the treatment of ELTs (end-of-life tyres) produces secondary raw material of various particle sizes, while separating other components such as steel and textile fibre.

PVC Profiles Plant

The plant designed by Camec allows the shredding of PVC profiles, no matter how long, with an automated loading system and effective separation of the materials.

WEEE Plant

The WEEE waste treatment plant produced by Camec has a treatment capacity that varies according to customer requirements and can process any type of discarded electrical and electronic equipment of the R1, R2, R3, R4 families.

Hospital Waste Plant

Camec hospital waste treatment plants are designed to meet strict regulations for the sterilisation and disposal of hazardous medical waste.

Special Waste Plant

Camec hazardous and non-hazardous waste plants are facilities designed to shred materials that contain toxic, flammable, corrosive or other hazardous waste.

Trainer Plant

This particular plant offered by Camec allows clean rubber to be obtained from discarded sports material, which can be reused and re-processed in line with a circular economy approach.

Pulper Waste and Rope Plant

The Camec pulper waste and rope treatment plant includes our patented solution that solves the needs of paper mills through a series of specific steps that separate the ferrous and non-ferrous fraction.

MSW Sorting Plant

In order to effectively sort MSW, a Camec sorting plant can be used, which makes it possible to separate the different components present in undifferentiated waste in an extremely precise manner and thus obtain recovered material, ready to be sent to recycling plants.

Tetra Pak® Plant

The plant designed by Camec can provide a versatile and compact solution for shredding Tetra Pak® containers, empty or otherwise, as required.

Photovoltaic Panel Treatment Plant

Photovoltaic panel treatment plants must be carefully designed and equipped with special machinery for shredding and screening the waste: CAMEC has developed various solutions for the treatment of category 4 WEEE.

Toner Cartridge Treatment Plant

Camec has developed a dedicated system for the proper shredding of spent toner cartridges that cannot be properly disposed of as municipal solid waste.

Composting Plant

The composting system developed by CAMEC consists of two main lines: the first is dedicated to treating organic material through a Waste crusher available in different configurations; the second, on the other hand, deals with processing branches through a double rotor.