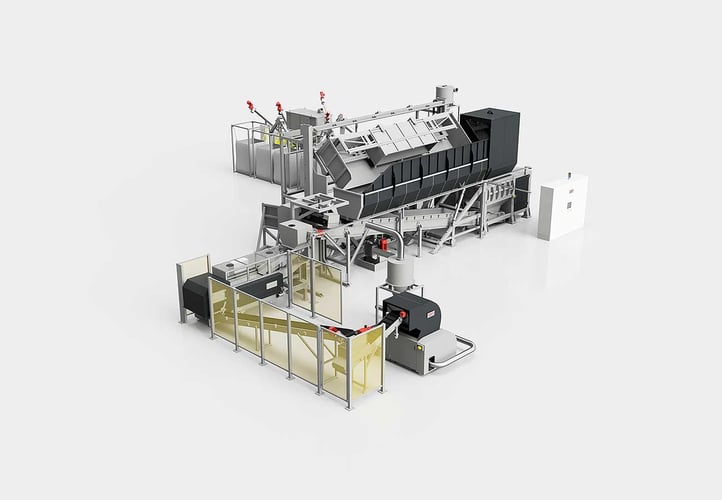

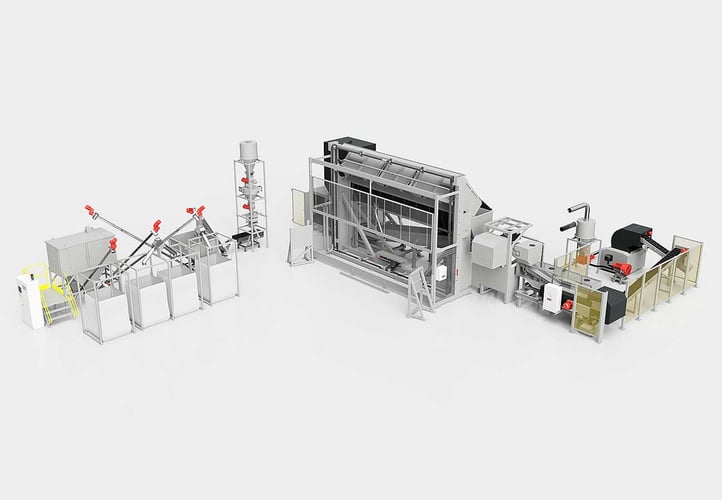

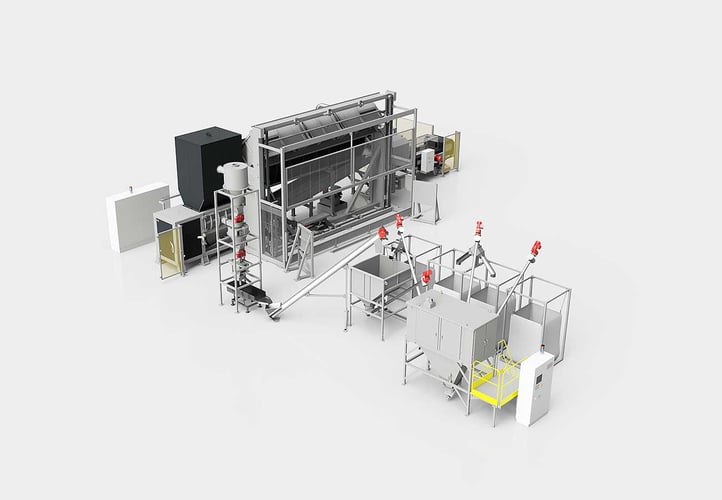

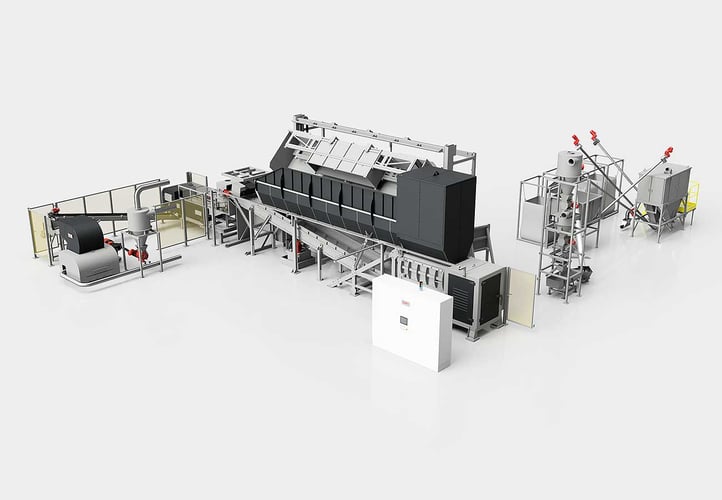

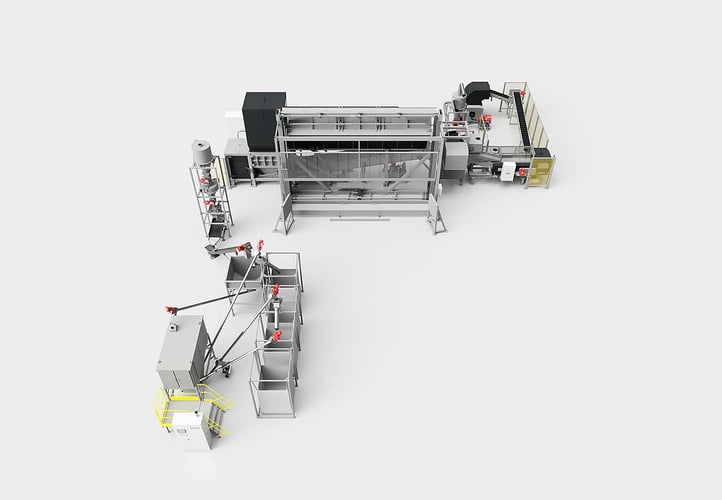

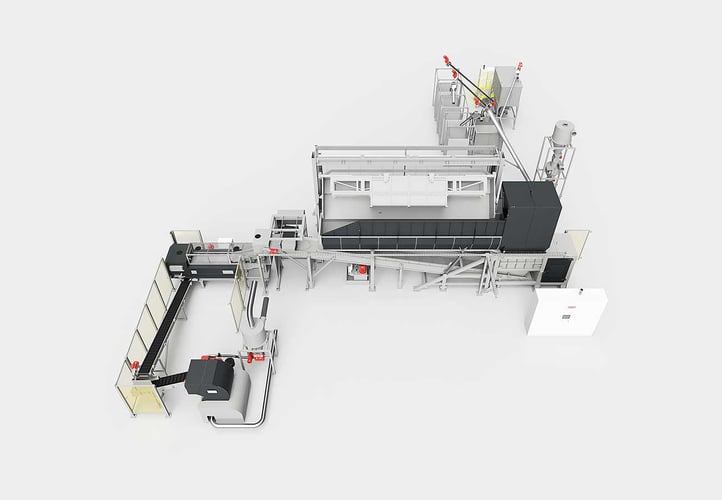

PVC Profiles Plant

The plant designed by Camec allows the shredding of PVC profiles, no matter how long, with an automated loading system and effective separation of the materials.

Description

The Camec plant allows the shredding of PVC profiles, including long ones, with an automatic loading system that can be customised according to customer requirements, in particular by allowing the use of tipping bins of different shapes and sizes.

The material then goes through a series of processes ranging from deferrisation to inductive current separation, from dedusting to metal detector separation for fine metal reduction.

Lastly, the triboelectric system completes the process, allowing the PVC to be separated from the gaskets to obtain a clean PVC ready to be reprocessed free of contaminants (metals, gaskets, etc.).