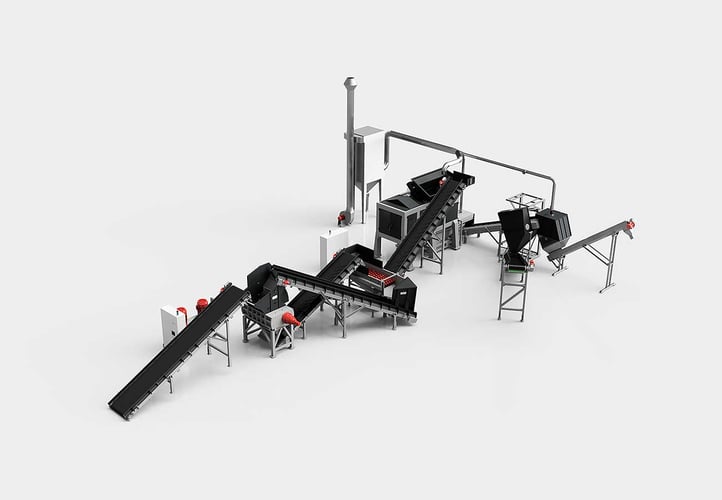

Tyre Plant

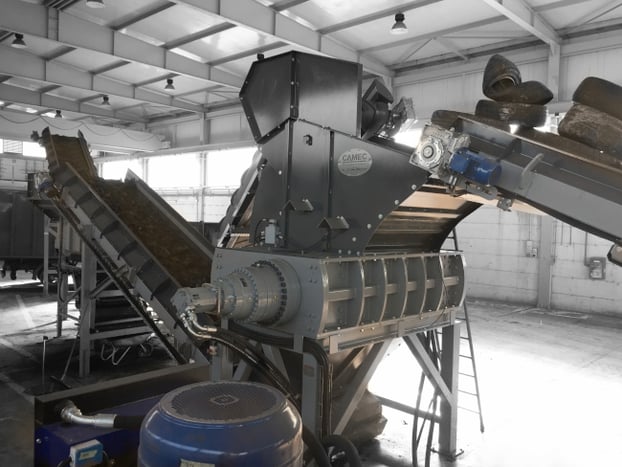

The Camec plant for the treatment of ELTs (end-of-life tyres) produces secondary raw material of various particle sizes, while separating other components such as steel and textile fibre.

Description

The Camec plant for the treatment of ELTs (end-of-life tyres) produces secondary raw material of various particle sizes, while separating other components such as steel and textile fibre.

The plant consists of four main stages, which can be carried out together in a single solution or in separate steps according to customer requirements.

The first part of the plant involves the shredding of the tyre using blade machine technology; the second part transforms the shredded rubber into 20 mm chipped rubber, generating the first separation of the ply and steel inside the tyre; the third stage transforms the chipped rubber into powder and further separates the ply and steel residue remaining from the previous stage. At the end of the treatment cycle, the fourth stage involves the total cleaning of the steel extracted from the tyre with 99% purity.